Introduction

In today's fast-paced world, industries are constantly seeking ways to improve efficiency, safety, and reliability in their operations. One crucial component that plays a significant role in achieving these goals is the use of heat-resistant shielded cables. These specialized cables are designed to withstand high temperatures, electromagnetic interference, and other environmental factors that can compromise the performance of standard cables. In this article, we will explore the numerous benefits of heat-resistant shielded cables across a wide range of industries and applications.

Benefits of Heat-Resistant Shielded Cables

1. High Temperature Resistance

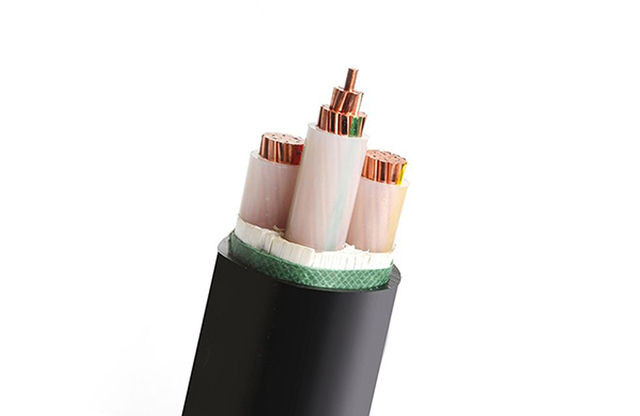

One of the primary benefits of heat-resistant shielded cables is their ability to withstand high temperatures. In insulated sheathed power cable , cables are exposed to extreme heat from machinery, engines, and other sources. Standard cables are not designed to handle such conditions and can quickly degrade, leading to malfunctions and safety hazards. Heat-resistant shielded cables, on the other hand, are made from materials that can withstand temperatures ranging from 150°C to 1000°C, depending on the specific type of cable. This high temperature resistance ensures reliable performance even in the most demanding environments.

2. Protection Against Electromagnetic Interference (EMI)

Electromagnetic interference (EMI) is a common problem in industrial settings where cables are exposed to various sources of electromagnetic radiation. EMI can cause signal distortion, data loss, and other issues that can disrupt operations and compromise safety. Heat-resistant shielded cables are constructed with a layer of shielding material such as aluminum foil or copper braid that provides protection against EMI. This shielding effectively blocks unwanted electromagnetic signals, ensuring that the transmitted data remains intact and reliable.

3. Enhanced Safety

Safety is a top priority in any industrial environment, and the use of heat-resistant shielded cables can contribute significantly to a safer workplace. Standard cables that are not designed to withstand high temperatures can pose a fire hazard when exposed to heat sources. In contrast, heat-resistant shielded cables are specifically engineered to resist flames and prevent the spread of fire, reducing the risk of accidents and injuries. Additionally, the shielding layer in these cables provides an extra layer of protection against electrical shocks and other hazards, ensuring the safety of personnel and equipment.

4. Improved Reliability and Performance

The reliability of cables is crucial in industrial applications where downtime can result in significant losses. Heat-resistant shielded cables are built to last, with durable materials that can withstand harsh conditions and frequent use. This durability translates to improved performance and longevity, reducing the need for frequent replacements and maintenance. As a result, industries can experience increased productivity and efficiency, as well as reduced operating costs over the long term.

5. Versatility and Flexibility

Heat-resistant shielded cables come in a variety of configurations to suit different applications and requirements. Whether you need cables for high-temperature environments, corrosive conditions, or areas with high levels of EMI, there is a heat-resistant shielded cable that can meet your needs. These cables are available in various sizes, lengths, and designs, making them versatile and adaptable to a wide range of industrial settings. Additionally, heat-resistant shielded cables are flexible and easy to install, allowing for seamless integration into existing systems without the need for extensive modifications.

6. Compliance with Industry Standards

In many industries, compliance with industry standards and regulations is essential to ensure the safety and reliability of equipment and systems. Heat-resistant shielded cables are designed and manufactured to meet stringent industry standards for performance, quality, and safety. By using these cables in their operations, industries can be confident that their systems are in compliance with relevant regulations and guidelines, reducing the risk of fines, penalties, and legal issues.

7. Cost-Effective Solution

While heat-resistant shielded cables may have a higher upfront cost compared to standard cables, they offer a cost-effective solution in the long run. The durability and reliability of these cables result in reduced maintenance and replacement costs over time, saving industries money in the form of fewer repairs and downtime. Additionally, the enhanced performance and safety provided by heat-resistant shielded cables can lead to increased productivity and efficiency, further contributing to cost savings in the long term.

Applications of Heat-Resistant Shielded Cables

Heat-resistant shielded cables find applications across a wide range of industries and sectors where high temperatures, EMI, and other environmental factors are present. Some common applications include:

1. Aerospace and Defense: Heat-resistant shielded cables are used in aircraft, military vehicles, and defense systems where reliable communication and data transmission are critical. The high temperature resistance and EMI protection of these cables make them ideal for aerospace and defense applications.

2. Automotive: In the automotive industry, heat-resistant shielded cables are used in engine compartments, exhaust systems, and other high-temperature areas to ensure reliable performance and safety. These cables help prevent overheating, signal interference, and electrical failures in vehicles.

3. Oil and Gas: Heat-resistant shielded cables are essential in oil and gas exploration and production facilities where high temperatures, corrosive environments, and EMI are common. These cables are used in drilling rigs, refineries, and pipelines to maintain communication and control systems under challenging conditions.

4. Industrial Automation: Heat-resistant shielded cables play a crucial role in industrial automation systems where machinery and equipment operate at high temperatures and are exposed to EMI. These cables ensure the smooth operation of robotic arms, conveyors, sensors, and other automated systems.

5. Energy and Utilities: In power plants, substations, and renewable energy facilities, heat-resistant shielded cables are used to transmit electricity safely and efficiently. These cables are designed to withstand high temperatures and harsh environmental conditions, making them ideal for energy and utility applications.

Conclusion

Heat-resistant shielded cables offer a wide range of benefits in various industries, including high temperature resistance, protection against EMI, enhanced safety, improved reliability and performance, versatility, compliance with industry standards, and cost-effectiveness. By using heat-resistant shielded cables in their operations, industries can ensure the safety, efficiency, and reliability of their systems, leading to increased productivity and cost savings in the long term. With their diverse applications and numerous advantages, heat-resistant shielded cables are a valuable asset in modern industrial environments.